Cummins develops two-stage turbo system with Nissan

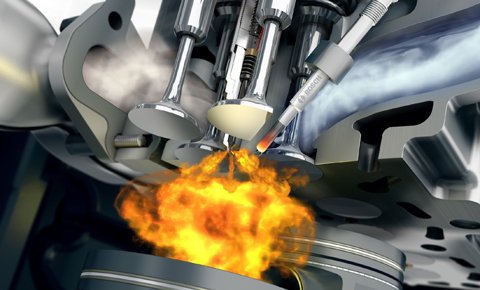

At IAA Hannover, Cummins Turbo Technologies unveiled its new Holset M² Two-Stage System with Rotary Turbine Control (RTC), which has been developed in partnership with the Cummins Engine Business and Nissan specifically for use on Nissan’s next generation Titan pickup truck.

The bespoke two-stage technology, developed at the company’s technical centers in Huddersfield, UK and Indiana, USA, was fitted to the Cummins 5-liter V8 turbo diesel engine and showcased in tandem with the engine at the show. It will offer flexible architecture that efficiently integrates and packages two turbochargers in series to deliver Nissan’s high-performance levels whilst still meeting the stringent emissions targets of the light-duty market.

Sitting within Cummins Turbo Technologies’ specialist modulated two-stage (M²) product range, the RTC technology, which is used to channel exhaust to the required areas for complete exhaust control capability, has four main operating modes:

• High Pressure Two-Stage Turbo Mode – Minimizes turbo lag and enables a better vehicle transient performance.

• Low Pressure Single Stage Turbo Mode – Enables higher power performance whilst ensuring smooth transparent mode transition without impacting vehicle driveability

• Wastegate Mode – Maximizes engine power output

• Regen Mode – Optimized aftertreatment operating conditions for emissions control

End users will benefit from a more responsive and efficient power control, creating a seamless driving experience.

“Engine manufacturers are increasingly looking towards turbocharging technology to help them achieve their emissions and efficiency goals,” says Jonathan Wood, executive director, research and engineering. “Advances in air-handling technology and improved system integration continue to provide new solutions that enable customers to achieve these goals without compromising engine performance. As part of that technology development journey we are unveiling this new addition to our suite of next generation, post Euro 6 technologies at IAA.

“We are delighted that Cummins Turbo Technologies has been selected as a solution provider by one of the biggest names in the industry. Nissan will be the first to benefit from this pioneering integrated technology, which delivers high efficiency, excellent driveability and the low emissions levels required in North America and Europe.

“As the turbocharger supplier of choice for many big name engine manufacturers, Cummins Turbo Technologies takes pride in our ability to partner with customers and develop bespoke solutions. This was clearly demonstrated during the development of this new technology where we have worked in a seamless partnership with the Cummins Engine team and Nissan to deliver this optimum system solution”

Cummins Turbo Technologies also showcased a number of next-generation innovations at IAA Hannover, systems capable of improving the fuel efficiency of modern diesel engines by at least 10%. Other solutions on show included the Electrical Waste Heat Recovery Turbine Expander – a prototype which uses an organic rankine cycle to capture what would otherwise be lost energy, in the form of heat. It turns this into useful electrical (5kWe) power that is capable of offering a supplementary way of feeding a hybrid system with additional power.

Also on display was the Next-Generation HE300VG – with improved turbocharger efficiencies of up to 12% enabling improved fuel efficiency and reduced carbon dioxide, this latest Holset VGT is 10% lighter than its existing counterpart, creating greater fuel economy. The solution offers multiple benefits, such as enhanced integration with the engine system thanks to a new actuator and also improved durability and optimized performance through the patented moving shroud VG mechanism

Cummins also showcased the Electric Wastegate, which offers two actuator options ensuring flexibility for different light and heavy-duty applications. Utilizing patented twin port technology that features an arrowhead lever design, it provides greater durability and robustness and with a faster response and more precise control, customers will benefit from improved engine performance, fuel efficiency and emissions control, as well as optimized aftertreatment.

Highly durable, highly efficient, compact turbochargers are becoming increasingly desirable, and with these new unveilings at IAA, Cummins Turbo Technologies will develop and expand on its current market-leading position in the design and manufacture of turbochargers for the commercial diesel engine sector.